Services

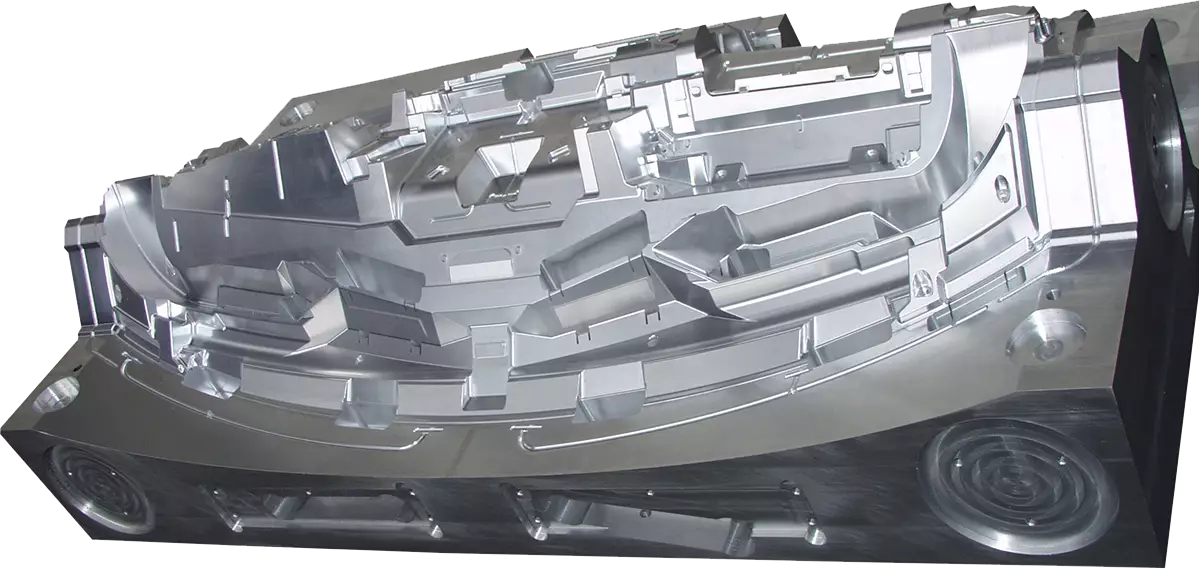

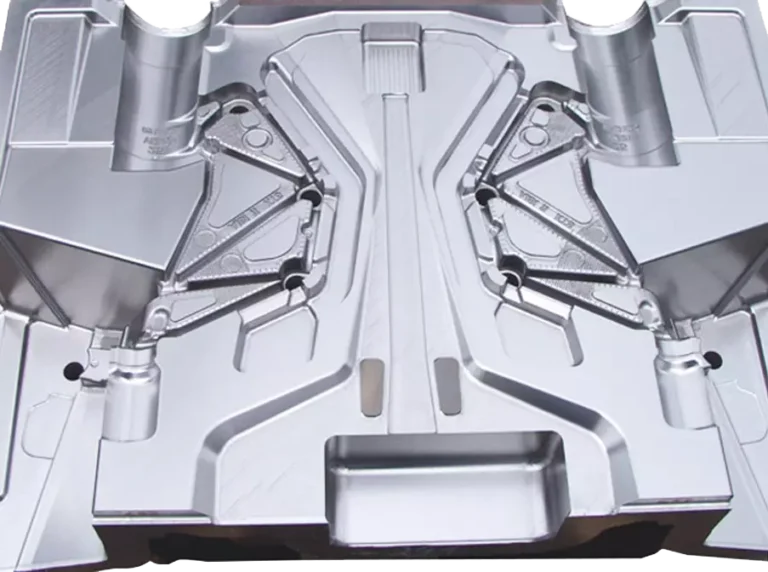

High Feedrate Cutting (HFC)

High Speed Cutting (HSC)

Core competence

High Feedrate Cutting (HFC)

- high metal removal rate

- controlled tool wear

- short machining time with defined residual material for subsequent finish machining

- reduced energy consumption of the machine tool

- reduced programming effort

High Speed Cutting (HSC)

- Low cutting forces lead to precise milling cutter running

- Heat dissipation via the chip and thus distortion-free machining

- High surface quality reduces time-consuming and costly reworking to a minimum

Quality Characteristics

Optimal surface quality

Highest precision

Economic manufacturing

Machine capacity

Highest accuracy and surface quality for 5-axis milling of large workpieces due to the use of linear motor technology

max. workpiece dimensions: 2200 mm x 2600 mm x 1250mm

max. workpiece weight: for 5-axis finishing: 16 t

max. speed: 16.000 rpm.

max. acceleration: 6m/s²

max. feed rate for finish milling: 20 m/min

Technical data of our machines

KEN Compact B

Speed range: 1 – 15,000 rpm

travels (X / Y /Z): 2.500 x 2.200 x 1.250 mm

Remarks:

Linear motor technology

workpiece weight: max. 16.000 kg,

simultaneous controlled 4th + 5th axis

clamping area 2.500x 2.500 mm, IKZ 65 bar

Hermle C50

speed range: 1 – 12.000 rpm

travels (X / Y /Z): 1.000 x 1.100 x 750 mm

Remarks:

workpiece weight: max. 2.500 kg,

simultaneous 4th + 5th axis,

chipping surface: Ø 1.150 mm

Hermle C40

speed range: 1 – 18.000 rpm

traverse paths (X / Y /Z): 850 x 700 x 500 mm

Remarks:

workpiece weight: max. 1.400 kg,

simultaneous 4th + 5th axis,

rotary table Ø 800 mm

DepoSpeed

speed range: 1 – 14.000 rpm

travels (X / Y /Z): 1.000 x 1.100 x 700 mm

Remarks:

Workpiece weight: max. 8.000 kg,

manual 4th + 5th axis

Trimill VC 1810

Speed range: 1 – 12.000 rpm

travels (X / Y /Z): 1.000 x 1.800 x 700 mm

Remarks:

Workpiece weight: max. 8,000 kg,

manual 4th and 5th axis

Hedelius C50

Speed range: 1 – 12.000 rpm

travels (X / Y /Z): 1.800 (also 2 x 750) x 500 x 500 mm

Remarks:

4th axis, IKZ 20 bar, pendulum operation possible

2 x Quick Jet AV128H

speed range: 1 – 14.000 rpm

travels (X / Y /Z): 1.200 x 800 x 700 mm

Remarks:

workpiece weight: max. 1.500 kg,

manual 4th + 5th axis